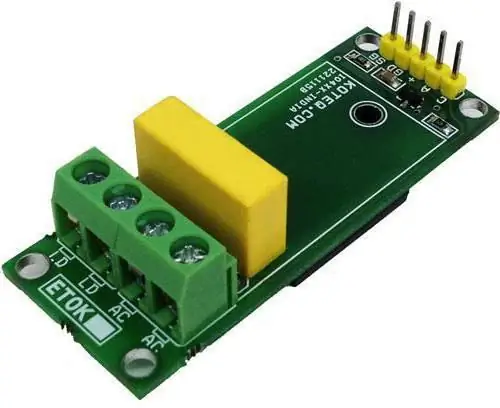

The most widely used solid state relay found in industry. Here it is used to create equipment that must be small and reliable. The abbreviation in Cyrillic looks like TTR, and in Latin SSR. The main disadvantage of these devices is the price. But within the framework of the article, we will only talk about the features and benefits that a solid state relay has.

Principle of operation and construction

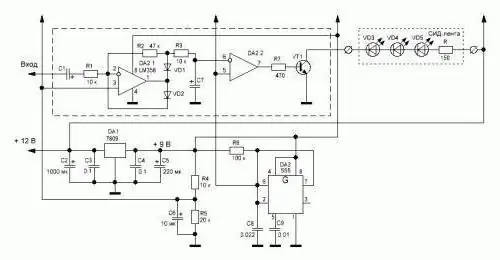

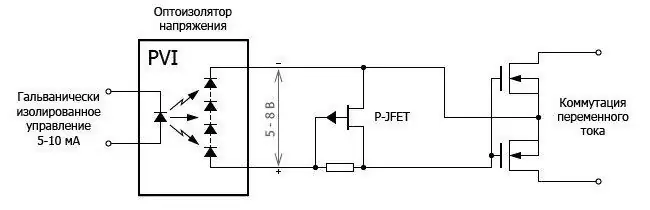

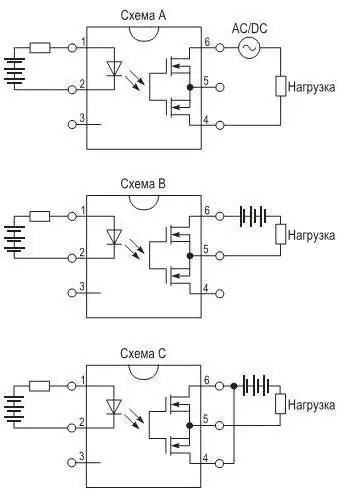

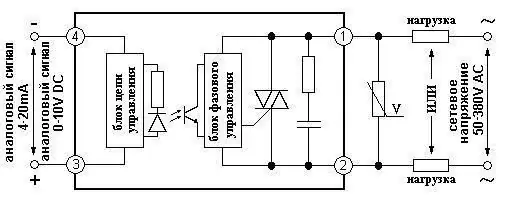

Let's first look at how a normal relay works. It is a device in which there are contacts and a control coil. For the device to work, we need a voltage with which to exert an influence. It will cause the contacts to open or close as it is applied to the coil. A solid state relay works in a similar way. Only here, instead of contacts, semiconductor devices are used. The most common are triacs, thyristors (to switch alternating current) and transistors (for direct current). Also, solid-state relays use galvanic isolation between the voltages at the power contacts and the coil. This is achieved due to the presence of an optocoupler at the input. If the functionality is implemented through thyristors andtriacs, then they say that we have AC solid-state relays.

Comparison

In general, each key transistor can be represented as a solid state relay. Let's remember how most motion or light sensors work. After all, they are created according to the principle according to which it is the transistor that supplies voltage to a conventional relay. Coil and semiconductor element as a contact. As for the use of triacs and thyristors, they can pass current in both directions (which is not available to the transistor). If we continue our comparison further, it is worth noting that significantly less energy is consumed and lost by solid state relays during operation. They are also small in size, high speed, long service life and absolute noiselessness. But, despite all the advantages, it is impossible to say that we will be able to abandon conventional relays in the near future.

Intraspecies differences

Distinguish solid state relay:

- Three-phase switches current in the range from 10 to 120 Amperes immediately on 3 phases.

- Reverse. Semiconductor devices that can carry out contactless switching of direct and alternating currents. In their main task, they coincide with single-phase relays. There must be a control circuit that provides protection against false inclusion. Reversing relays are characterized by three-phase operation and long service life. This is possible thanks tohigh-quality control mechanism and isolation, which are provided structurally for this type of device. When operating these devices, there is no acoustic noise, bounce when switching and sparking.

- Single-phase provides current switching when it passes through zero. The solid-state single-phase relay operates in the range from 10 to 500 amperes. Control can be done in four ways.

Applications

Solid State Relays are used where it is necessary to adhere to the principle of set and forget about it. For comparison, consider an example. But before that, consider an excerpt from the instructions for ordinary contacts: even the manufacturer recommends cleaning them after several thousand circuits.

But now for an example. The company has a machine on which solenoid valves are installed. Their power supply is 24VDC 2A. They are connected in parallel. Turn off/off approximately once per second. Power is supplied through a relay. Even if it can withstand 10 amperes of inductive load, then it will have to be changed once a month or two. Whereas a solid state relay will allow you to forget about it for years. Although no one canceled the scheduled technical inspection. In this regard, it is advisable to focus on the recommendations received from the manufacturer in the accompanying documentation.

Indications for use

If ordinary contacts do not cope with their duties, they burn like candles, then this is the best recommendation for use. Solid state relays can providework reliability. They handle inductive loads with ease. Also, if you need to take care that the contacts do not stick, or there is a strict size limit, solid state relays will come to your rescue.

What are the types of solid state relays?

They are divided according to their device, as well as the principle of operation. For ease of understanding, I propose the following classification:

Depending on the type of control voltage:

- Constant (discrete).

- Variable.

Depending on the type of switched voltage:

- Variable.

- Permanent.

Depending on the number of AC voltage phases:

- Singles.

- Triple. There is also the possibility of dividing according to the presence or absence of a reverse.

According to design features (where installation is carried out):

- On the surface.

- On DIN rail.

Choosing a solid state relay

Some features should be noted. So, conventional relays can easily withstand short-term overloads, the value of which will be 150% or even 200% of the nominal value. If everything is done correctly, then cleaning the contacts can be dispensed with in all cases. With a solid state relay, this is not possible. So, if you exceed the figure by 150%, you can safely throw away the device. Therefore, for an active load, a margin of 2-4 times should be provided for the rated current. If aa solid state relay will be used to run induction motors, this figure will need to be increased by 6-10 times. Such a reserve, although it forces you to choose more expensive parts, at the same time allows you to guarantee a long service life of the device to which the device is connected.

Add-ons for correct work

When interacting with an inductive load, structures can function with certain problems. Therefore, when working with transformers, electric bells, coils with magnetic cores and similar devices, it is necessary to connect an RC circuit in parallel to reduce the effect of back-EMF. It will also reduce the overall load inductance, and the solid state relay will be easier to operate.

Short circuit protection

Manufacturers in this case recommend the use of special fuses that were developed for solid-state devices. Here is their classification:

- gR - fuses operating with the entire range of operating currents. They are used to protect semiconductor elements. Considered very fast acting.

- gS - work with the entire range of operating currents. Used when the line is under heavy load, and as a protection for semiconductor elements.

- aR - fuses that work with the entire range of operating currents. Used to protect semiconductor elements from short circuits.

It should be noted that fuses are quite expensive. Therefore, incircuit breakers (class B) are used as an alternative.

Where can I buy?

You can buy AC solid state relays at your nearest radio electronics store. But this applies, as a rule, to those cases where the reader's place of residence is a large city. If this is not the case, you can be advised to use the services of online stores. They usually provide delivery to the recipient for a certain amount or free of charge.

And what can be said directly about the cost that a solid state relay has? The price of these devices ranges from 600 rubles to several thousand.

Connecting a solid state relay

There is nothing difficult in this action. So that the device works, it is necessary to apply a control voltage to the input, observing the polarity. Let's talk about the features of this process:

- It is desirable to make connections using a screw method, and not by soldering.

- To avoid the situation with damage to the device, it is necessary to check the absence of dust, as well as elements of a metallic nature.

- Try to do everything possible so that there are no unacceptable external influences on the body of the device (both during operation and when it is turned off).

- Do not touch the relay while it is running to avoid burns. Also make sure that the device is not near flammable materials.

- When connecting, make sure that the correctconnection switching.

- If the device heats up more than 60 degrees during its operation, you need to get a cooling radiator for it.

- Care should be taken to ensure that there is no short circuit at the output of the device. Otherwise, it will simply fail.

Direct control of a solid state relay can be done with a circuit that provides various options. It is mounted on the plus-input.

Conclusion

We covered the solid state relay, principle of operation, control, types, protection - everything that matters. Of course, this is not enough to independently mount such a device in most cases.